What You Need to Know About Heat Transfer Printing!

juin 11, 2025

Heat transfer printing is widely used in various irregular ceramics, containers, textiles, product labels, and other fields. Due to its convenience and the ability to customize colors and patterns, it is a favored technique among brand owners, boasting promising market prospects. Let’s delve deeper into this process with us!

Heat Transfer Printing

Heat transfer printing is a process that transfers graphic information from an intermediate carrier to the surface or subsurface of a substrate through the application of heat and pressure. It is a specialized form of printing that evolves from traditional printing methods, integrating and merging with various industrial technologies.

Principles of Heat Transfer Printing

The process involves pre-printing colored patterns onto a heat-resistant base film (treated with a release agent) and then using specialized transfer equipment to heat-press the design onto the product surface. The quality of heat transfer printing is reliable, with stable technology, excellent material formulations, and seamless equipment integration.

Classification of Heat Transfer Printing

Heat transfer printing, also known as heat press printing, can be categorized as follows:

- High-Temperature Heat Transfer: Primarily used for cotton and blended knitwear, such as T-shirts and pajamas. The patterns have a photographic effect and remain soft and elastic after pressing.

2. Low-Temperature Heat Transfer: Mainly applied to nylon fabrics and PU synthetic leather, such as sportswear, swimsuits, down jackets, athletic shoes, and leather gloves. The pattern effect is similar to high-temperature heat transfer, with excellent elasticity for stretchable clothing.

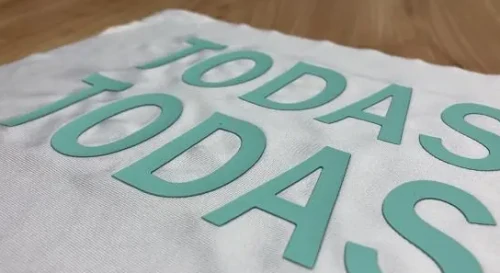

3. Flocked Heat Transfer: Suitable for a wide range of applications, including women’s stockings, men’s cotton socks, clothing labels, and knitwear for children. The patterns have a 3D effect, allow multi-color combinations, and remain soft, elastic, and highly adhesive after pressing.

4. Penetration Foam Heat Transfer: Used for cotton, synthetic knitwear, wool sweaters, and jeans. The key feature is the penetration into the fabric, providing good breathability. The foamed areas have a strong 3D effect, raised texture, and remain soft and highly adhesive after pressing.

Heat Transfer Printing Methods

1. Sublimation Transfer: Also known as gas-phase heat transfer, this method uses dye-based inks that can sublimate. The image, landscape, or text is printed in reverse on paper via offset, screen, or gravure printing. The printed paper is then placed on the substrate, and heat (around 200℃) and pressure are applied to transform the ink from solid to gas, transferring the design onto the substrate.

2. Heat Press Transfer: This method involves screen printing (or gravure printing) the design onto heat transfer paper or film, followed by heat pressing to transfer the design onto the substrate. With the popularity of laser and inkjet printers, many small workshops now use laser printers to directly print designs onto transfer paper or use inkjet printers to print on regular paper, which is then photocopied onto transfer paper. Finally, the design is heat-pressed onto the substrate.

Key Differences Between the Two Methods:

– Sublimation transfer is mainly used for synthetic fabrics and hard materials coated with a heat transfer layer, while heat press transfer is primarily applied to cotton products.

– Sublimation transfer preserves the original texture of the material, offering excellent feel and appearance. Heat press transfer forms a layer of adhesive on the surface, resulting in a less breathable and inferior feel.

– Both methods have their unique advantages and characteristics in production.

.png)

.png)

.png)